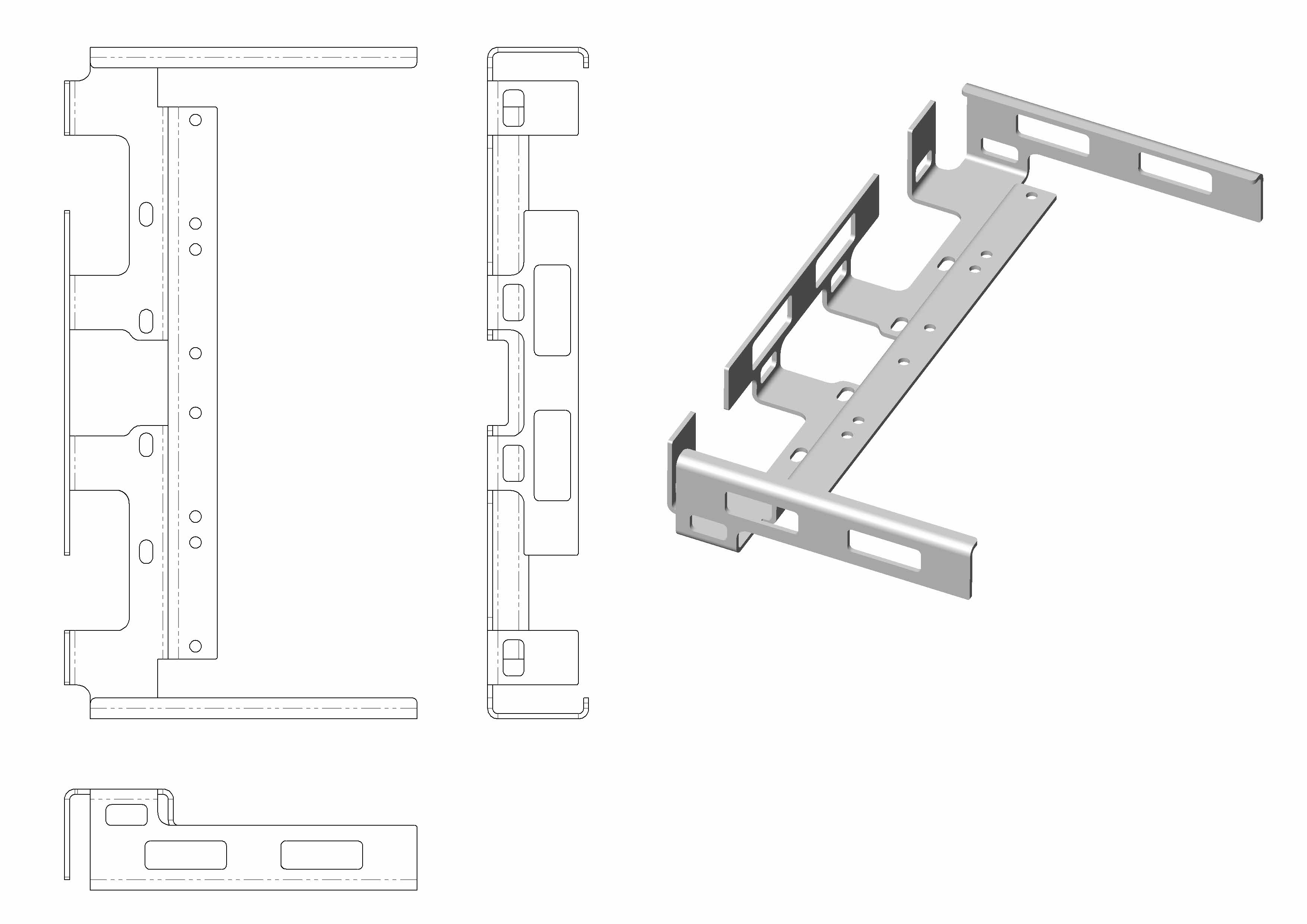

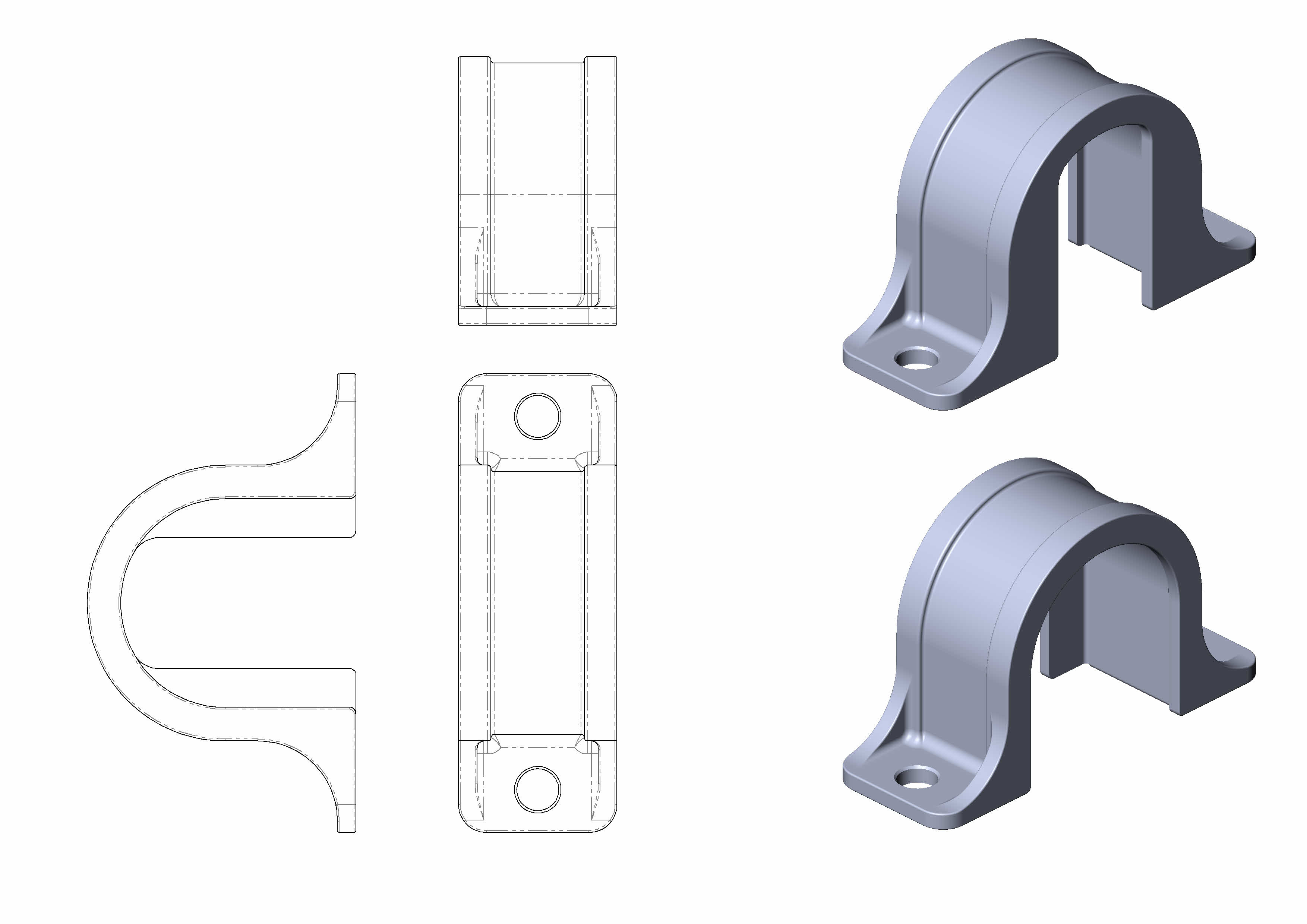

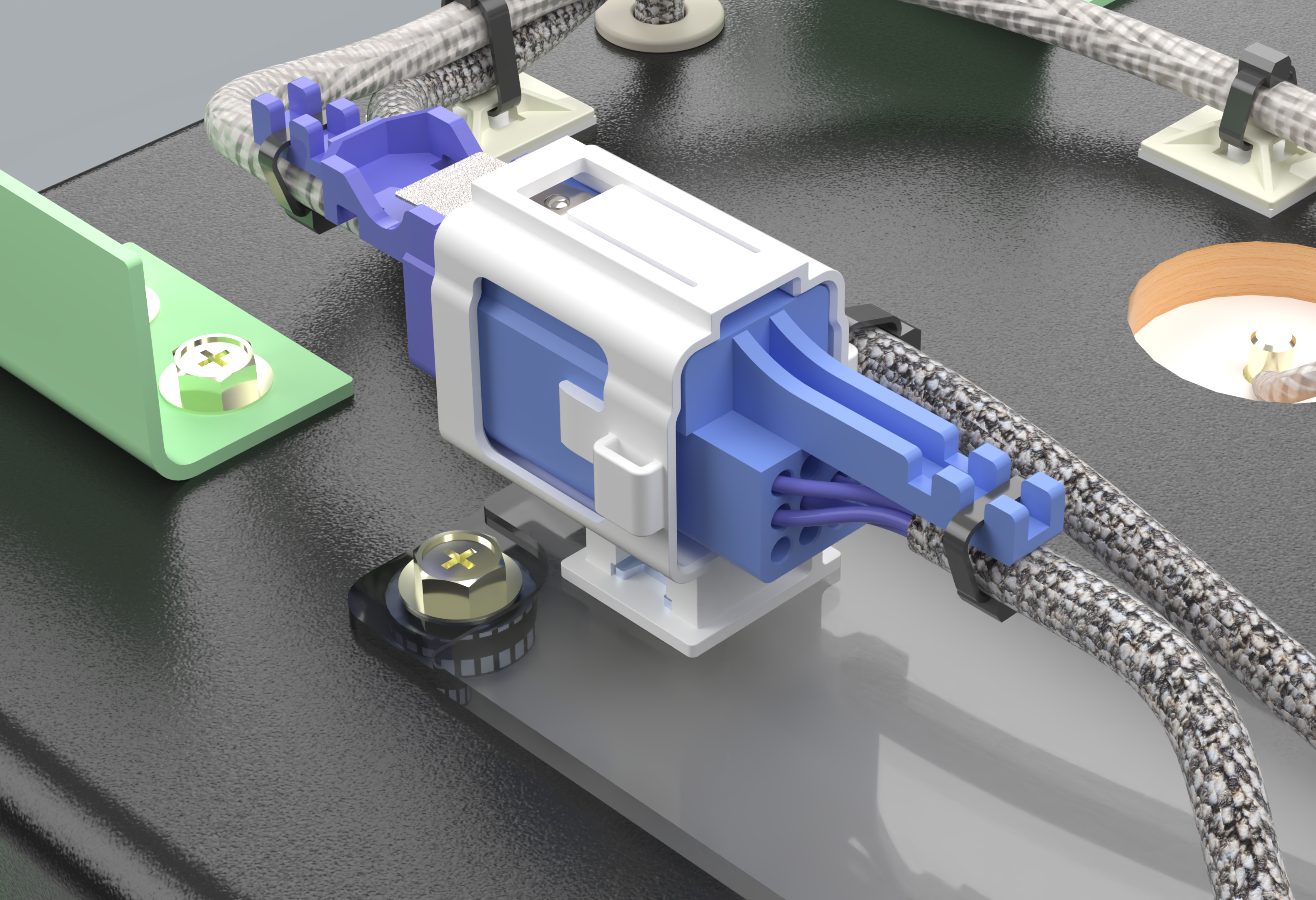

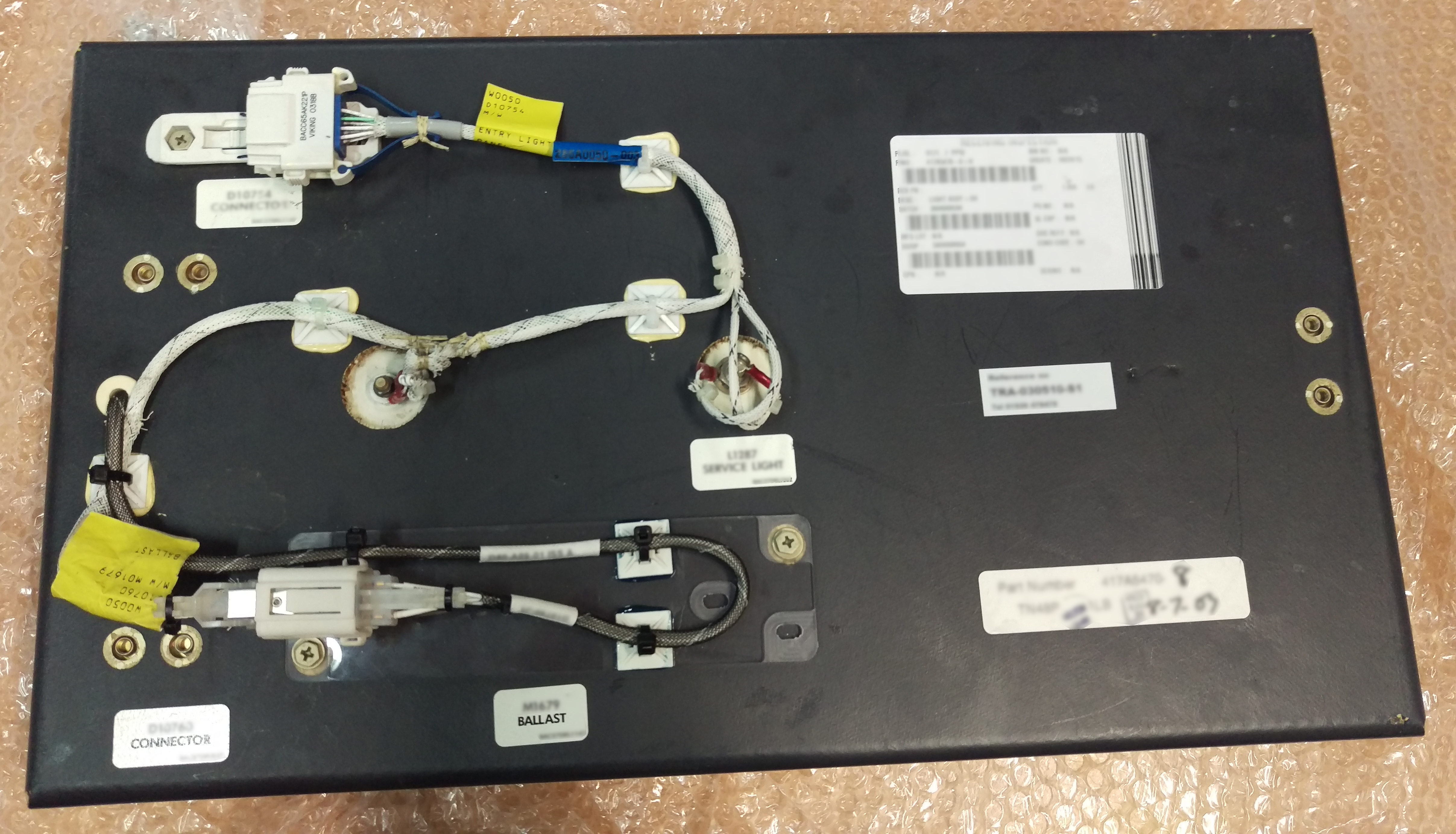

Detail from documentation showing just some of the OEM parts to be replaced.

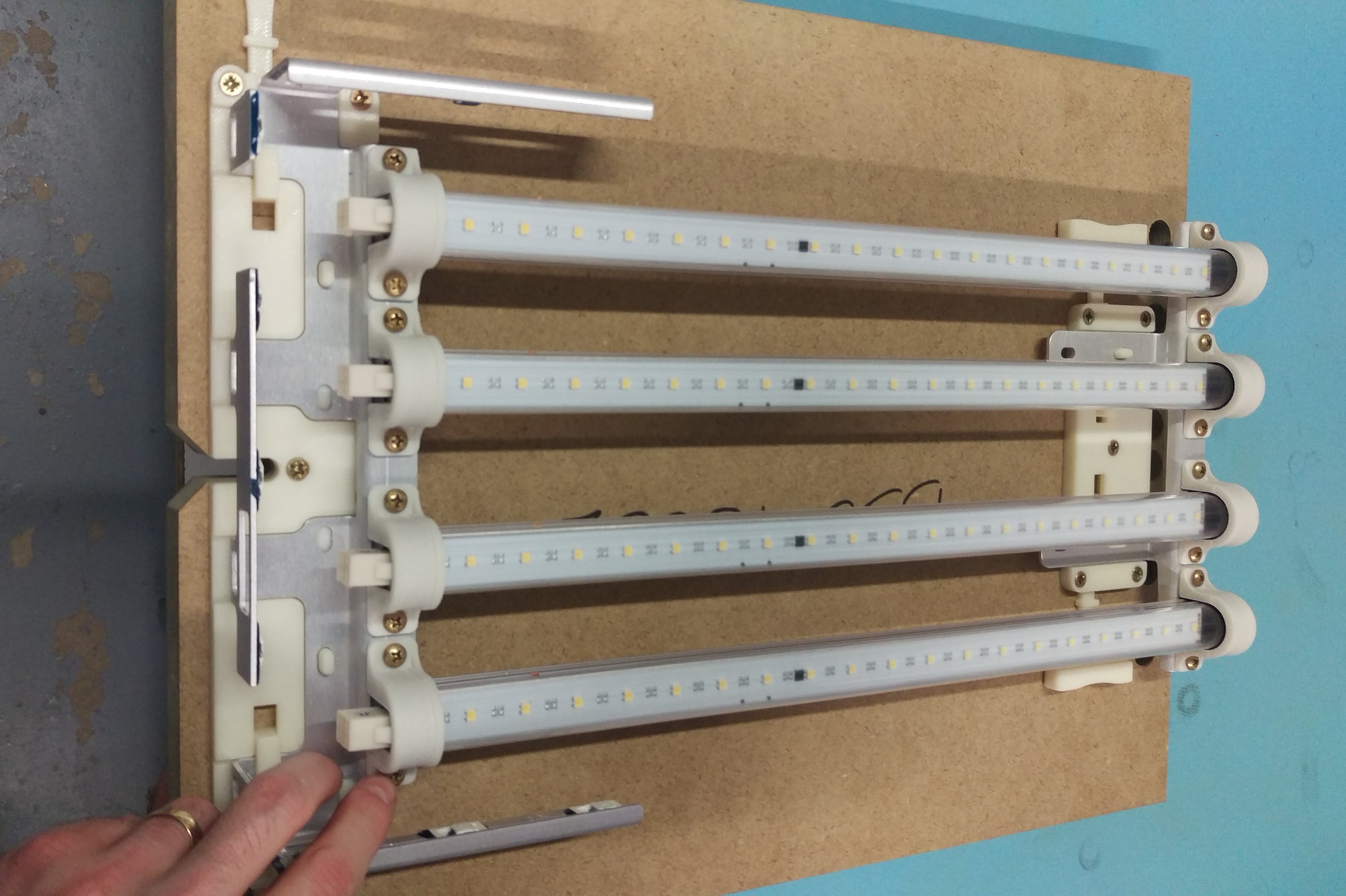

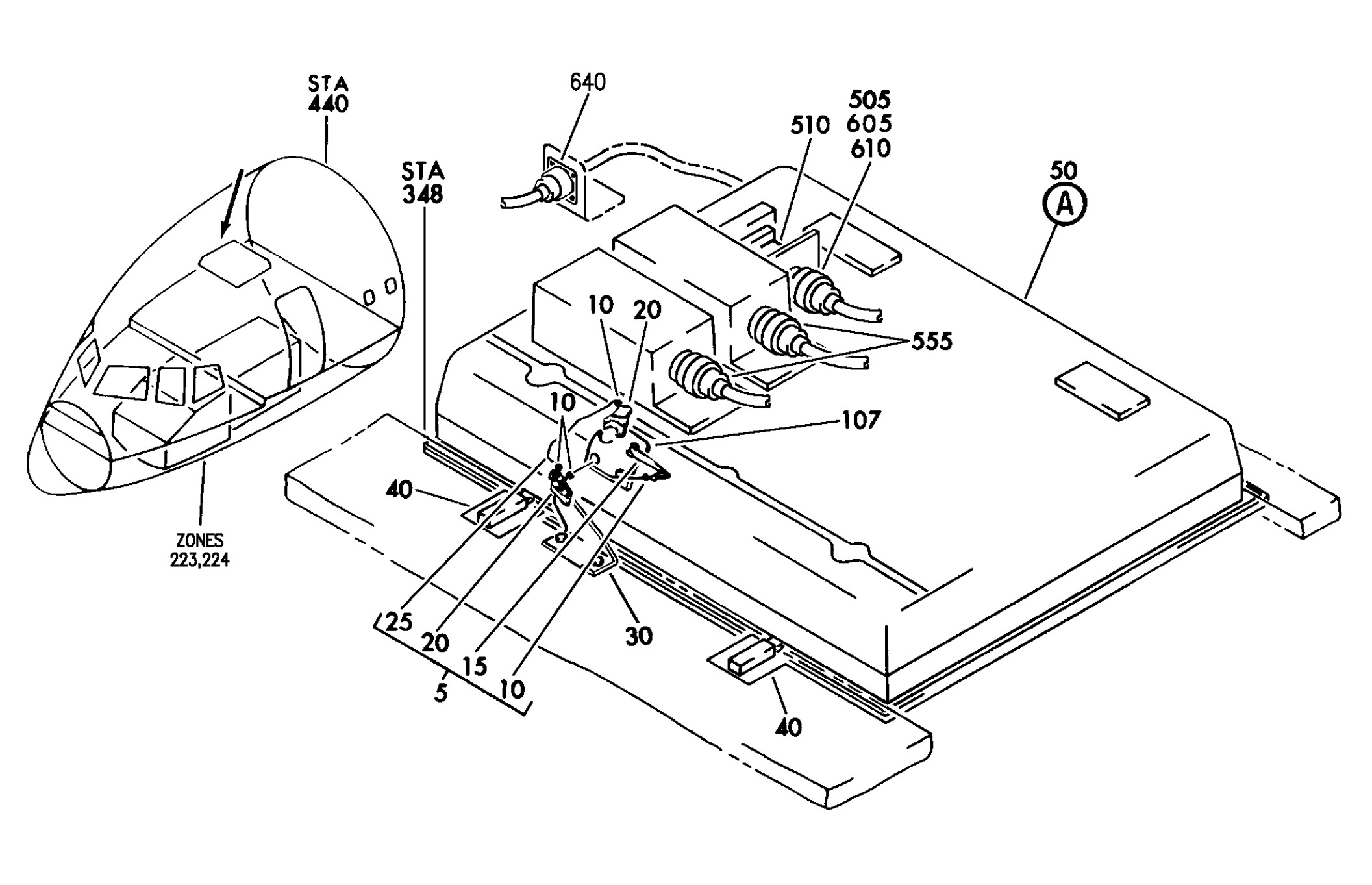

Having had the need for a new product identified, we investigated the OEM variants to understand how existing lamp units could be integrated into a new design whilst ensuring that there was no weight gain (a key requirement).