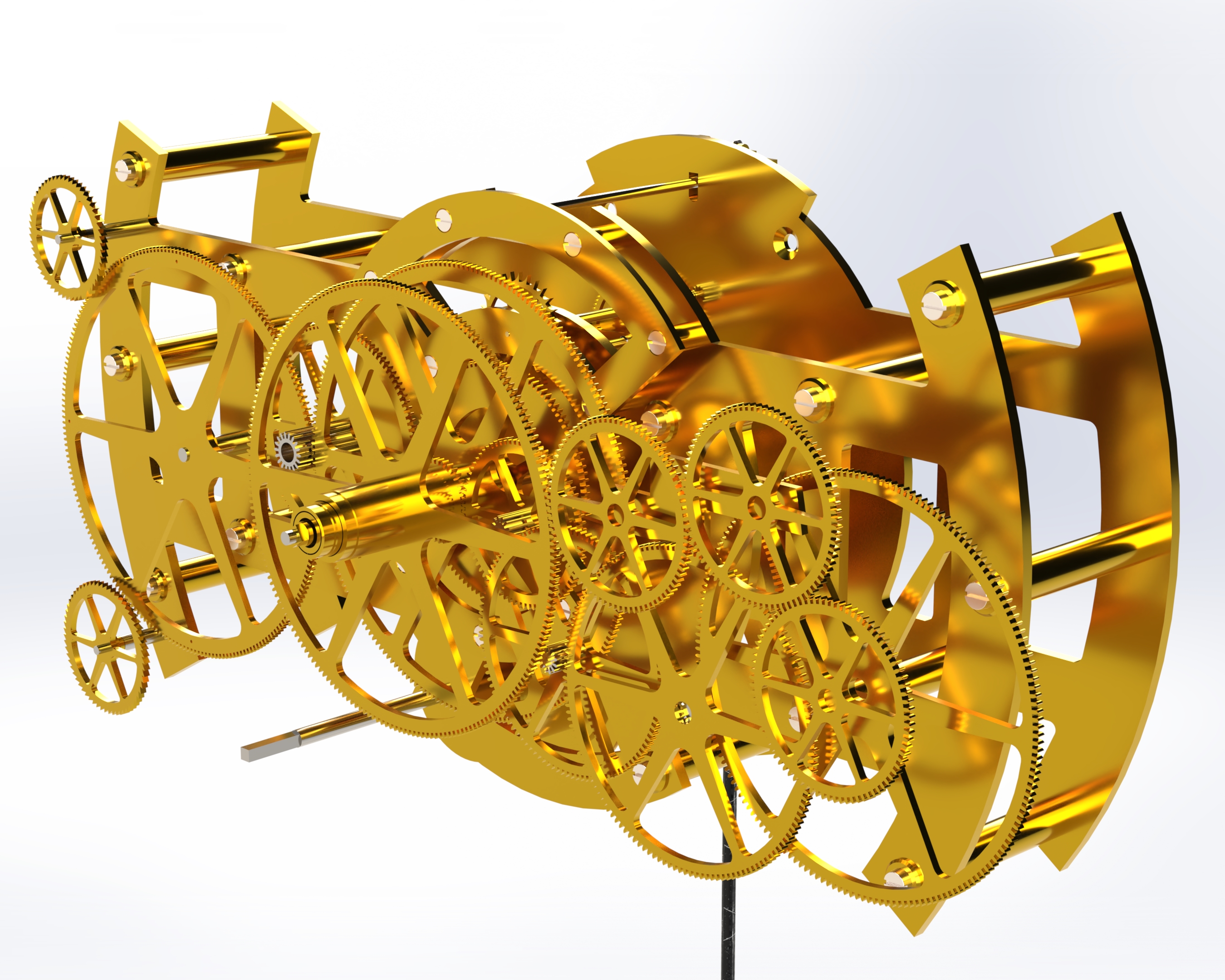

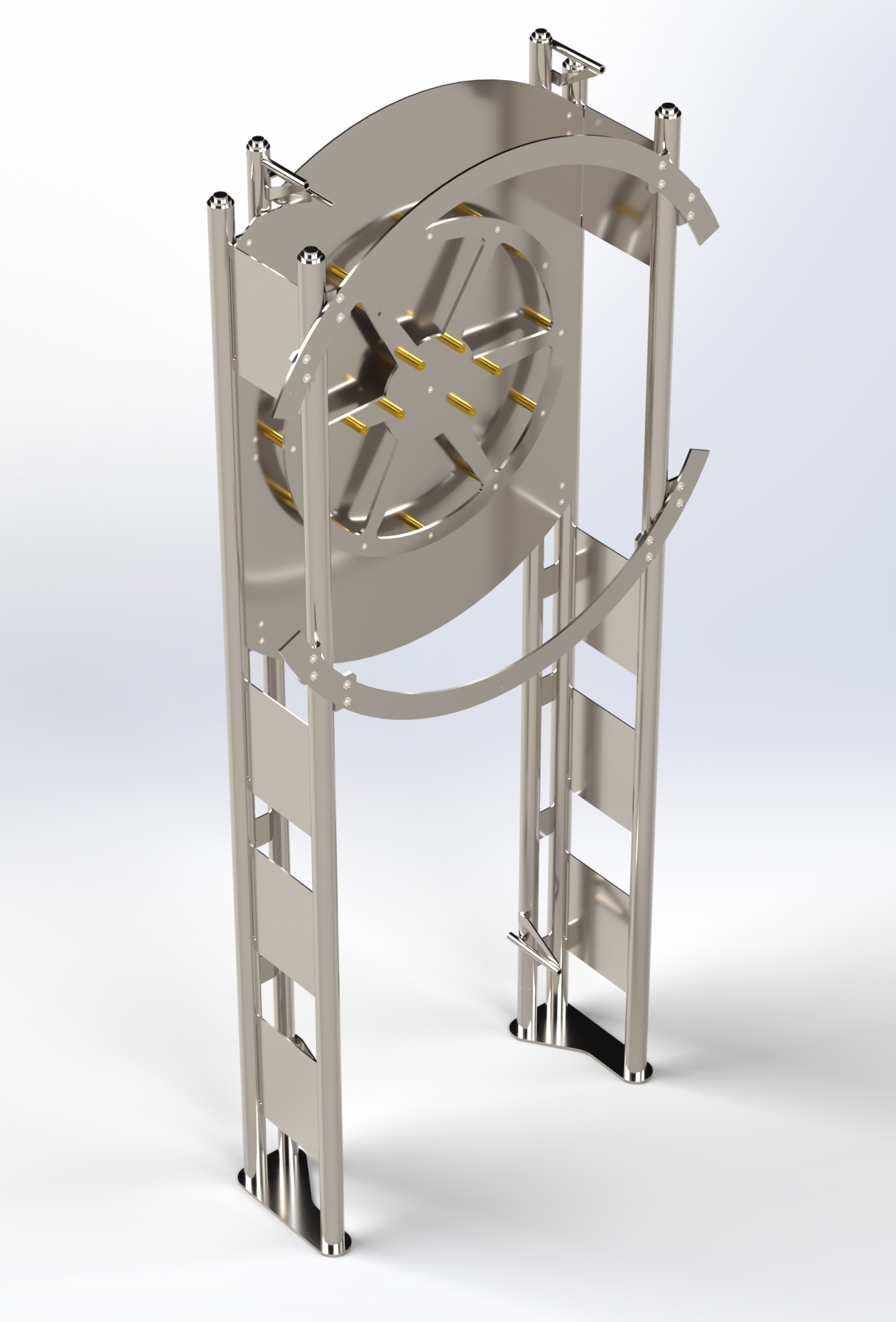

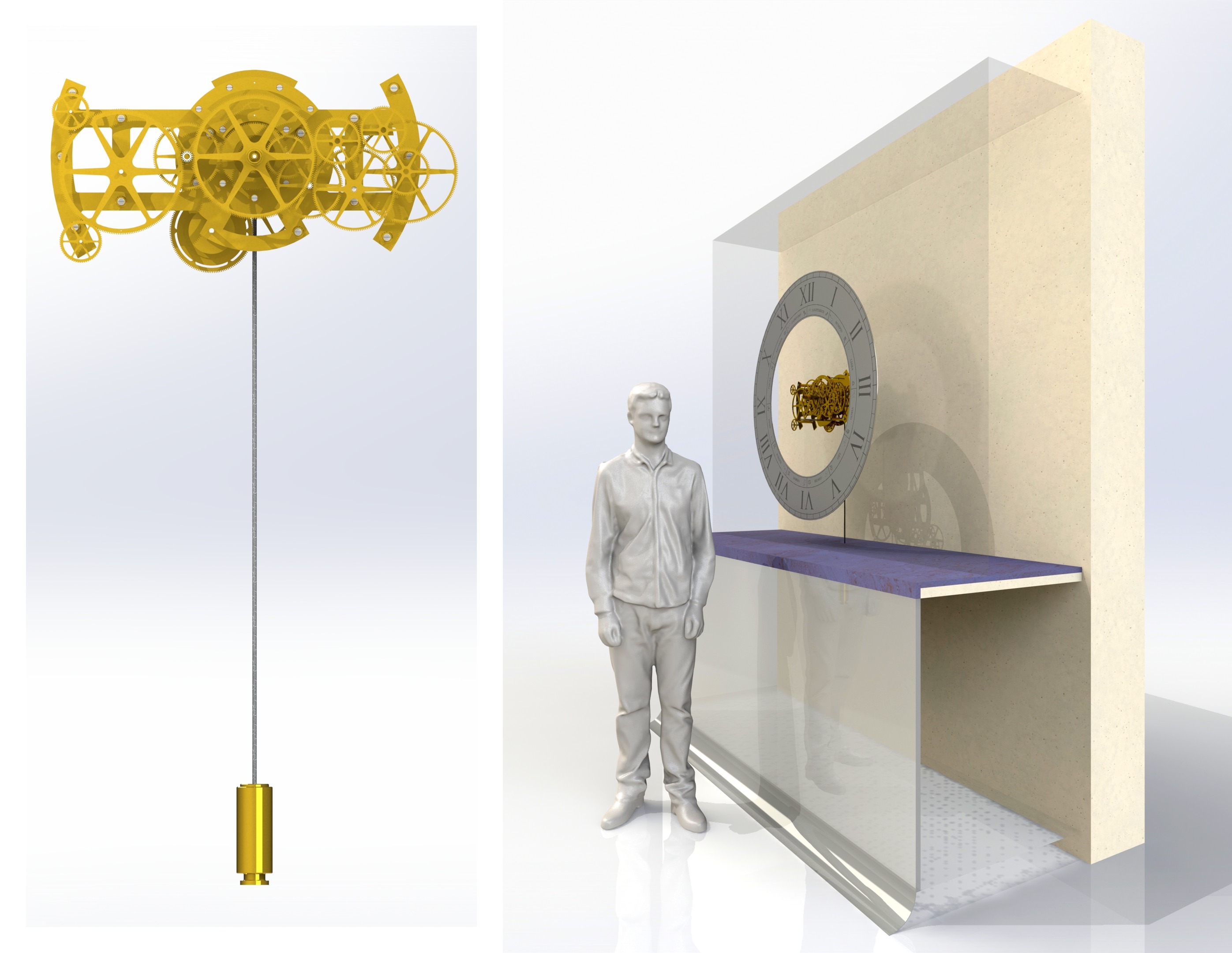

An early design image submitted to the client for commercial and contract approval

After consulting on the brief from the American client we provided concept visualisations to help secure the contract. Combining Simmonds Clockmaking's extensive horological expertise with our industrial design and manufacturing skills we co-operated to produce a design that met the client brief and in their own words surpassed their expectations.